Hey there! 👋

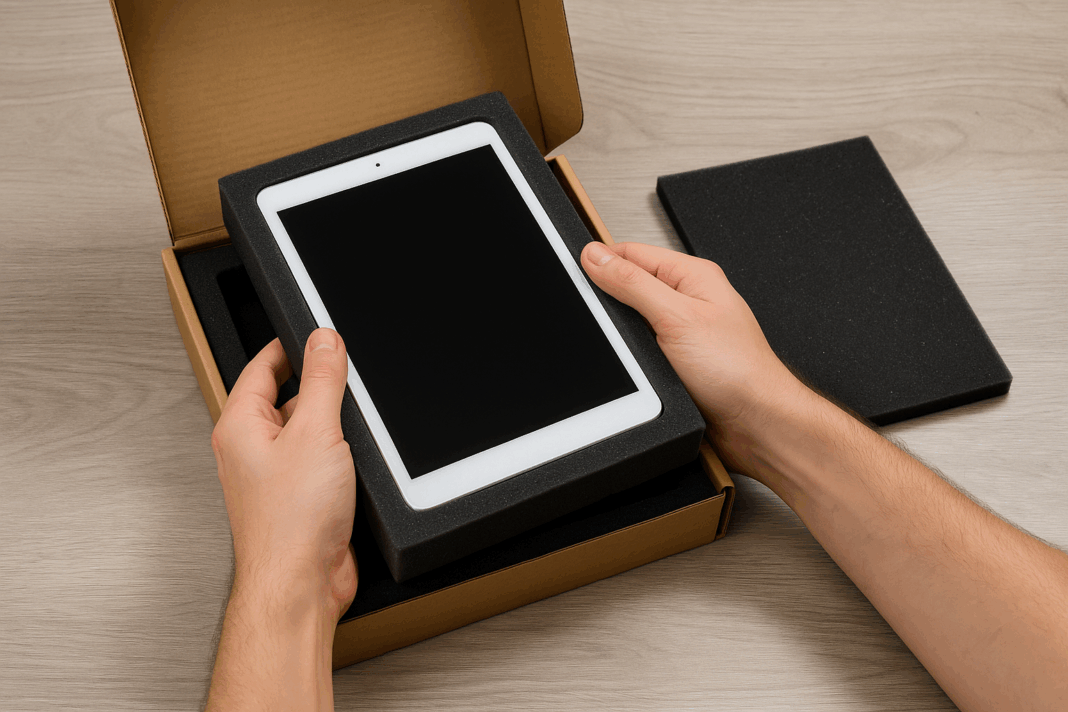

Let me tell you about the time I received a $1,200 camera lens that looked like it had been through a wrestling match. 📦🥊 The box was pristine, but inside? Absolute chaos! That lens taught me more about electronics packaging than any textbook ever could. Today, I’m sharing how the right foam can be your secret weapon against such heartbreaks.

The Silent Guardian: Why Electronics Need Foam Protection

Picture this: Your brand new smartphone traveling through a delivery network. It faces drops, vibrations, temperature swings, and pressure changes. Without proper protection, it’s like sending a porcelain vase through a pinball machine! 🎯 That’s where specialized foam comes in.

I remember working with a drone manufacturer who had 23% damage rates during shipping. After switching to custom-molded polyethylene foam, their returns dropped to just 4% within three months. That’s the power of foam!

The Science Behind the Squish: How Foam Works Its Magic

Quality foam doesn’t just cushion – it strategically absorbs and redistributes energy. Think of it as a shock-absorbing superhero! 💥🦸 Here’s what happens during a 4-foot drop (a common shipping hazard):

| Protection Type | G-Force Reduction | Product Survival Rate |

|---|---|---|

| Bubble Wrap | 40-50G | 65% |

| Loose Fill Peanuts | 30-45G | 72% |

| Physically cross linked polyethylene foam | 15-25G | 98% |

The secret lies in foam’s ability to compress gradually, slowing down deceleration. It’s like jumping into a safety net versus concrete!

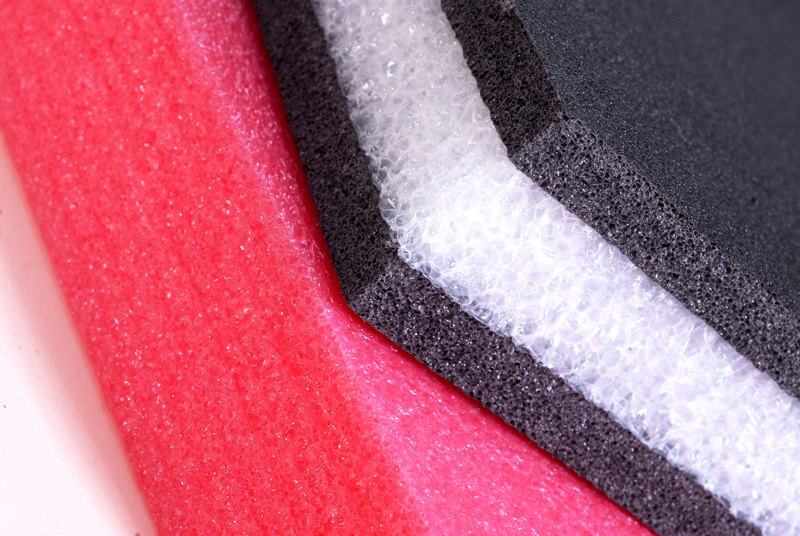

Beyond Shock: Foam’s Multi-Layered Protection

Great electronics packaging is like an onion 🧅 – it needs multiple protective layers:

- Anti-Static Protection ⚡: Prevents electrostatic discharge that fries circuits

- Moisture Resistance 💧: Creates a barrier against humidity and condensation

- Contamination Control 🛡️: Keeps dust and particles away from sensitive components

I once visited a circuit board factory where they used standard packing peanuts. The static electricity alone caused 12% failure rates! Switching to anti-static pe foam solved it immediately.

Real-World Impact: When Foam Saves the Day

Let me share a game-changing case study: A medical device company shipped sensitive monitors worth $3,500 each. Despite “fragile” stickers, 15% arrived damaged. After implementing custom chemically cross linked polyethylene foam inserts:

- ✅ Damage claims dropped to 0.8%

- ✅ Customer satisfaction jumped 41%

- ✅ Product returns decreased by $380K annually

Their VP told me: “This foam pays for itself ten times over!” 💰

Choosing Your Foam: A Practical Guide

Not all foams are created equal! Through years of trial and error, I’ve developed this simple selection framework:

Step 1: Know Your Enemy 🎯

What threats does your product face? Drops? Vibration? Moisture? Conduct a packaging hazard analysis.

Step 2: Density Matters 📏

Higher density (kg/m³) = better protection but more weight. Find the sweet spot!

Step 3: Compression is Key ⚖️

Will your product experience stacking pressure? Choose foam with appropriate compression resistance.

The Sustainability Angle: Foam’s Hidden Benefit

Here’s what most people miss: Proper foam protection is eco-friendly! ♻️ By preventing product damage, you:

- Reduce return shipping emissions 🚚

- Cut manufacturing waste from replacements 🏭

- Extend product lifespan by preventing “hidden damage” 🔍

A client making audio equipment discovered their products lasted 18% longer in customer homes simply because foam prevented internal component stress during shipping. Mind-blowing, right? 🤯

Future-Proof Packaging: Emerging Foam Tech

The foam world is innovating fast! My current obsessions:

Smart Foams 🤖: Embedded sensors that monitor impacts during transit and change color if excessive force occurs.

Phase-Change Materials ❄️: Foams that absorb heat during temperature spikes, protecting sensitive electronics.

Bio-Based Options 🌱: Sustainable foams made from plant materials with identical protective qualities.

Your Action Plan: Getting Started

Ready to transform your electronics packaging? Here’s my battle-tested approach:

- Conduct a Packaging Autopsy 🔍: Open a damaged return and analyze failure points

- Test, Test, Test! 🧪: Simulate shipping hazards with different foam solutions

- Partner with Experts 🤝: Find foam specialists who understand electronics

Remember that camera lens I mentioned? Today, it would be safely nestled in custom polyethylene foam cutouts. Don’t let your products become shipping casualties – give them the foam armor they deserve! 🛡️✨

You should also read these…

- axtly.com – you will be surprised to hear the uses of pe foam

- surgeblog.com – beyond grit the underrated power of strategic quit

- huesly.com – how cross linked polyethylene foam from durfoam im

- surgeblog.com – fixing disc cannot be read errors on consoles

- beofme.com – how to insulate properly with physical and chemica

- closedad.com – robust gearboxes reducers for industrial power tra

- axtly.com – thermal sound and moisture insulation at home durf

- spyfrogs.com – robo advisors vs financial planners pros and cons

- getaluck.com – twitter x unwanted mentions tags mention controls

- huesly.com – the dark side of edtech screen time and child deve