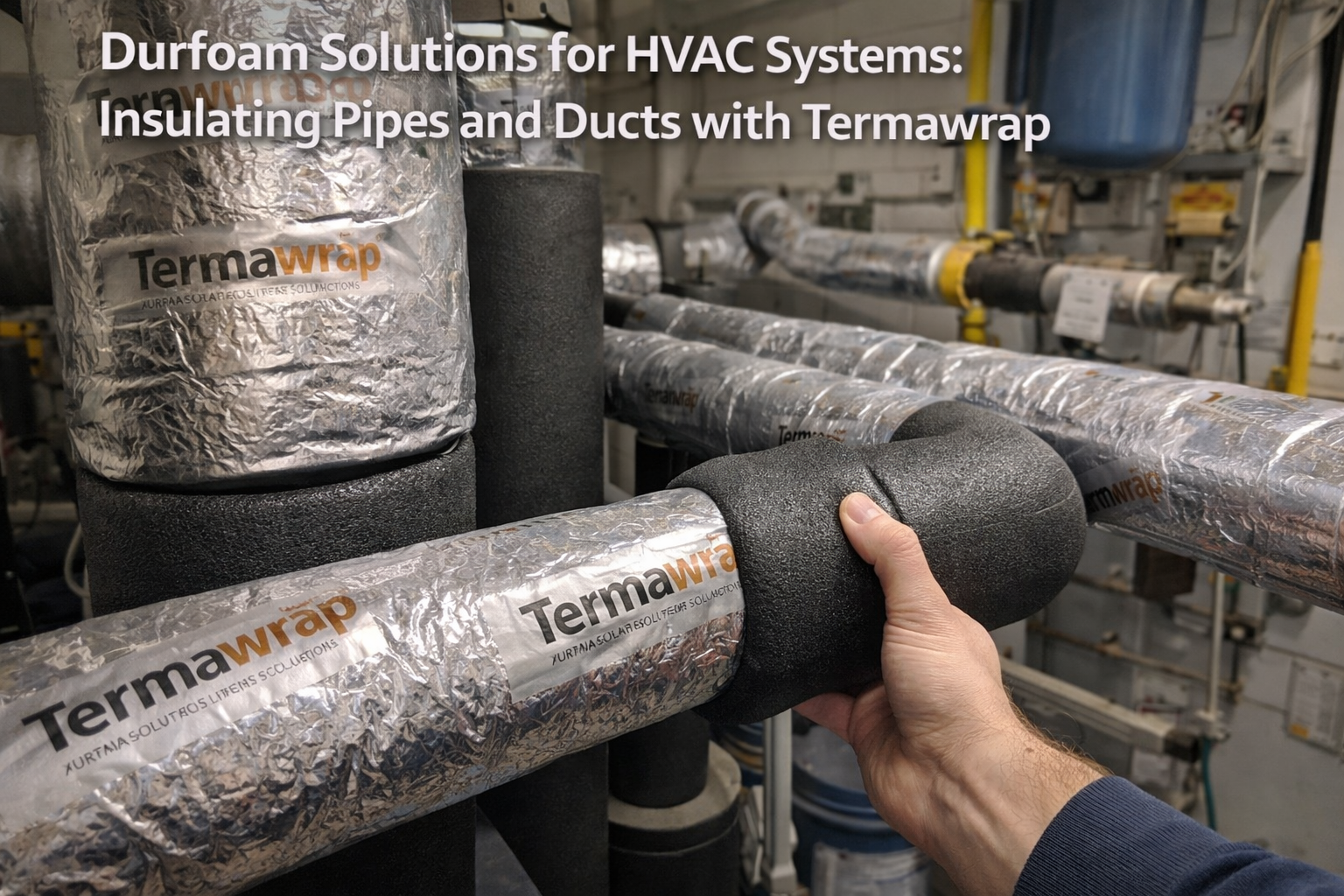

I remember the first time I walked through a commercial HVAC installation site — the maze of shiny ducts, compressors, and insulated pipes looked like something straight out of a science fiction movie. 🌬️ But what truly fascinated me was how a material as lightweight as foam could make such a big difference in keeping buildings energy-efficient and comfortable. That’s when I first encountered Durfoam’s Termawrap solutions — a line of advanced insulation products designed specifically for HVAC systems, where precision, performance, and reliability matter most.

In the world of heating, ventilation, and air conditioning, thermal losses are a constant enemy. Every uninsulated duct or pipe is a tiny leak in your energy budget. Durfoam tackles this issue with its Termawrap insulation range made from polyethylene foam, known for its closed-cell structure that prevents heat exchange and condensation. The result? Consistent airflow temperatures, reduced energy consumption, and long-lasting system efficiency. ⚙️

What sets Termawrap apart is its ability to insulate while also resisting moisture, vibration, and temperature fluctuations. The foam’s structure creates a continuous thermal barrier, preventing condensation on cold surfaces — a common issue that leads to corrosion, mold, and reduced indoor air quality. Whether it’s an industrial plant or a commercial office tower, Durfoam ensures both comfort and protection. 🏢

Here’s a practical comparison to highlight why physically cross linked polyethylene foam and chemically cross linked polyethylene foam outperform traditional insulation materials in HVAC applications:

| Material | Thermal Conductivity (W/m·K) | Water Absorption | Durability |

|---|---|---|---|

| Fiberglass Wrap | 0.040 | High | Moderate |

| Rubber Insulation | 0.038 | Medium | Good |

| Durfoam Termawrap (PE Foam) | 0.032 🌡️ | Very Low | Excellent |

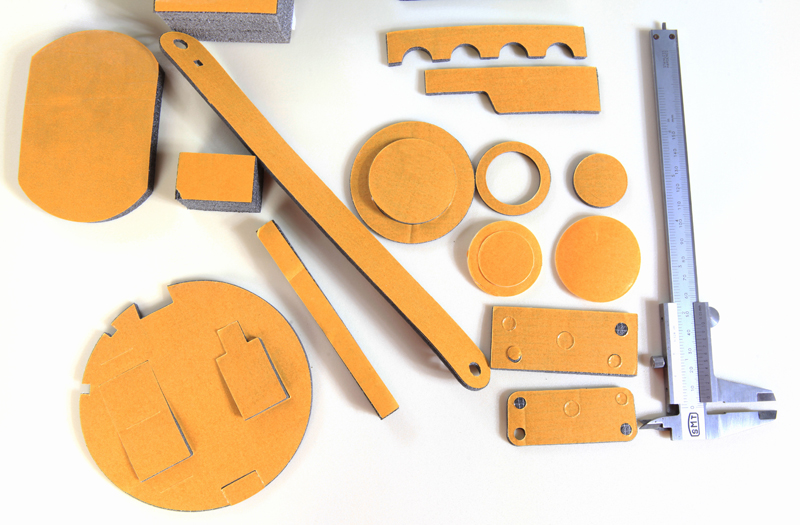

In practice, this means HVAC systems wrapped in Termawrap maintain their designed performance levels for years, requiring minimal maintenance. The foam’s flexibility allows it to fit around complex shapes — elbows, joints, and irregular ducts — without creating gaps that could lead to energy loss. Contractors I’ve spoken to love working with it because it’s clean, easy to install, and doesn’t release fibers or dust like traditional insulation materials. 🧰

Another advantage lies in condensation control. By using closed-cell foam, pe foam acts as both a thermal and vapor barrier, eliminating the need for additional layers. That translates to faster installation, lower labor costs, and longer system life — all while maintaining a neat, professional appearance. 💧

From an environmental perspective, Durfoam continues to lead by example. The Termawrap line is manufactured using recyclable materials, without harmful chemicals or CFCs, and in compliance with RoHS and REACH standards. These products not only improve efficiency but also support sustainable building certifications like BREEAM and LEED. 🌱

Here’s how I like to summarize the benefits of Durfoam’s Termawrap insulation in a single equation:

Durfoam Termawrap = Energy Efficiency + Moisture Control + Long-Term Reliability ✅

During my tour of Durfoam’s facility, I was amazed at the level of precision involved in quality control. Each production batch is tested for density, water absorption, and thermal conductivity to ensure consistent performance. The engineering team explained how even the smallest change in cell size can affect the insulation value — a reminder of how science and craftsmanship come together in every roll of Termawrap. 🧪

To give you a sense of where this innovation comes to life, here’s the map of Durfoam’s production center 👇

In conclusion, when it comes to efficient, durable, and environmentally responsible HVAC insulation, Durfoam’s Termawrap stands out as a clear leader. By combining closed-cell technology with years of expertise, it ensures that every system runs quietly, efficiently, and sustainably — from the first installation to decades down the line. 🌬️🏢✨