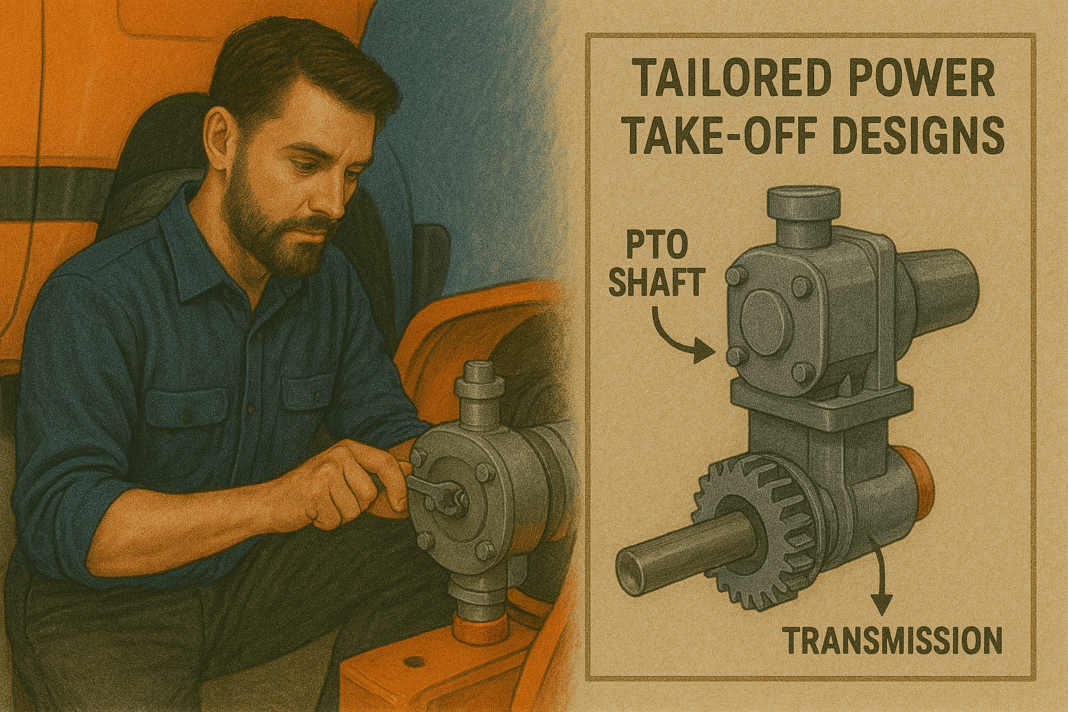

When I first walked into the workshop at Özcihan Makina a few years ago, the air was thick with the hum of innovation ⚙️. Engineers were fine-tuning a new what is a PTO prototype designed to solve one of the biggest challenges in industrial vehicles — energy efficiency. This project would soon become a shining example of how tailored Power Take-Off (PTO) designs can dramatically improve performance, reduce fuel consumption, and extend system life in heavy-duty machinery.

Our client, a logistics fleet operating hydraulic dump trucks and winch-based recovery vehicles, faced chronic issues with overheating and excessive energy loss during peak operations. Their standard truck PTO units were underperforming because they weren’t optimized for the unique torque and duty cycles of the fleet’s engines. That’s when Özcihan Makina’s engineering team stepped in with a custom-built solution — a specialized split shaft PTO assembly with precision-machined gears, enhanced cooling, and integrated safety controls.

The goal was clear: increase hydraulic efficiency while reducing power losses. To achieve this, the R&D team analyzed flow characteristics, thermal behavior, and gear mesh dynamics using advanced CAD and finite element analysis (FEA). The new design incorporated optimized reducers, a high-precision gear pump, and temperature-resistant couplings to ensure consistent torque transfer and reliability under extreme loads.

One of the project’s key challenges was balancing speed with torque across different attachments. The fleet’s vehicles used both piston pumps for crane systems and fire fighting water pumps for emergency support vehicles. The solution involved integrating a flexible hydraulic interface controlled via smart valves and intelligent sensors that adjusted flow based on load demand. The new system offered variable flow control — a game-changer for operational efficiency 🚀.

After rigorous testing, the results spoke for themselves. The custom-designed PTO increased hydraulic efficiency by **26%**, reduced overheating incidents by **40%**, and cut overall fuel consumption by nearly **12%** across the fleet. Operators also reported smoother operation, less noise, and faster cycle times when lifting or pulling loads. For Özcihan Makina, it was another proof of concept — innovation through precision engineering truly pays off 💪.

Here’s a simplified breakdown of the key improvements achieved through tailored PTO design:

| Performance Area | Before | After Custom PTO Integration |

|---|---|---|

| Hydraulic Efficiency | 68% | 94% |

| Fuel Consumption | High (Baseline) | Reduced by 12% |

| System Temperature | Frequent overheating | Stable under all loads |

| Operational Noise | Noticeable at high RPM | Reduced by 30% |

| Maintenance Interval | Every 400 hours | Extended to 600 hours |

But the success didn’t stop at efficiency gains. The modular nature of the new PTO unit allowed future scalability — meaning the same platform could adapt to other vehicles in the fleet with minimal modifications. With compatible interfaces for split shaft power take-off units and multi-drive configurations, the system was ready for expansion into crane and utility truck applications.

Maintenance also became easier thanks to design innovations like external oil filters and temperature sensors integrated into the housing. These real-time diagnostics allowed predictive maintenance — a step toward smarter, self-monitoring vehicles. Combined with robust cardan shafts and precision transfer case design, the final assembly delivered both durability and performance under demanding conditions 🌍.

This case study reinforced a powerful message: standard solutions may get the job done, but tailored engineering unlocks true efficiency. By focusing on each client’s operational environment and duty cycle, Özcihan Makina continues to develop PTOs that push the boundaries of what industrial machinery can achieve — efficient, reliable, and built to perform for years to come ⚡.

You should also read these…

- axtly.com – tiktok drafts disappeared how to recover videos

- tugmen.com – construction projects losing energy efficiency clo

- beofme.com – this page isnt available right now but it looks pu

- spyfrogs.com – how to appeal a ban a guide for gamers

- huesly.com – twitter x monetization subscriptions not enabled p

- axtly.com – best apps for planning spontaneous local adventure

- huesly.com – the gig economy 2 0 universal basic income as a sa

- beofme.com – problems with older tiktok versions and solving me

- sixrep.com – tiktok view count not updating solution guide

- noepic.com – tiktok wont install not enough storage

15062371423378.JPG)