When I first started learning about insulation materials, I never imagined that something as simple as foam thickness could have such a huge impact on comfort and energy efficiency. 🏡 Whether you’re building a new home, renovating a commercial facility, or just curious about improving your energy savings, understanding how to choose the right foam thickness and density can make all the difference. And if there’s one brand that’s mastered this balance, it’s Durfoam.

Let’s start with the basics: **polyethylene foam** is a closed-cell material, meaning it’s made up of countless tiny air pockets that trap heat and block moisture. Its effectiveness as an insulator depends primarily on two factors — thickness and density. Thickness controls how much thermal resistance (R-value) the foam provides, while density affects its mechanical strength and durability. The trick is finding a sweet spot between these two for your specific project needs. 💡

I once worked with an architect designing an eco-friendly residence in Istanbul who used Durfoam panels of varying thicknesses throughout the building. Walls used 20 mm **physically cross linked polyethylene foam**, while floors featured thicker 30 mm variants for better sound and heat insulation. The result? A stable indoor temperature year-round and a significant reduction in HVAC energy consumption.

Here’s a simple comparison table to help you visualize how thickness and density affect performance 👇

| Foam Thickness (mm) | Density (kg/m³) | Recommended Use | Key Benefit |

|---|---|---|---|

| 10 – 15 | 25 – 30 | Wall insulation, soundproofing | Lightweight and flexible |

| 20 – 30 | 30 – 40 | Floor insulation, HVAC ducts | High compression resistance |

| 40+ | 40+ | Industrial and roof applications | Maximum thermal retention 🔥 |

Choosing the wrong density can be just as problematic as choosing the wrong thickness. If the foam is too soft, it might compress over time, losing its insulation value. On the other hand, if it’s too dense, it could be over-engineered (and overpriced) for your application. That’s why experts at Durfoam often recommend balancing these properties based on your climate, building design, and insulation location.

For instance, **chemically cross linked polyethylene foam** is excellent for areas exposed to higher temperatures or moisture, such as roofs or basements. Its dense structure prevents vapor infiltration and helps maintain long-term insulation performance. On the other hand, **physically cross linked polyethylene foam** is often used in interior applications where flexibility and lightweight performance are more important.

During my factory visit to Durfoam’s facility, one of the engineers explained it perfectly: “Think of density as the muscle and thickness as the shield.” That metaphor stuck with me — it’s all about finding harmony. The company’s ability to fine-tune both factors ensures that its foams perform consistently across different construction types and climates. 🧱

It’s also worth noting that **pe foam** insulation contributes to sustainability goals. It’s recyclable, lightweight (reducing transport emissions), and helps lower household energy use — all aligning with green building certifications like LEED. 🌱

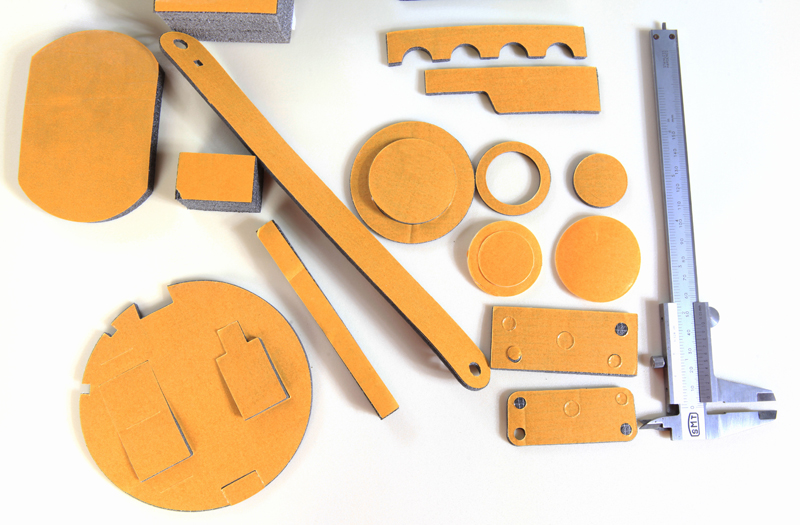

Here’s where all this smart innovation happens 👇

And if you’d like to see how Durfoam manufactures these precision-engineered foams, this video gives a fantastic behind-the-scenes look:

In conclusion, selecting the right foam thickness and density isn’t just a technical decision — it’s an investment in comfort, sustainability, and performance. By choosing Durfoam, you’re not only getting reliable materials but also the expertise of a company that understands how science translates into everyday living comfort. ✨

You should also read these…

- soturk.com – locked accounts on game platforms steam epic

- godwig.com – funniest spin the wheel dares to play with friends

- godwig.com – how acoustic foams improve sound insulation in bui

- noepic.com – sorry something went wrong infinite loop how to de

- tugmen.com – why does tiktok family pairing disconnect

- hogwar.com – video and upload problems and solve method on tikt

- axtly.com – cant join twitter x spaces microphone permissions

- soturk.com – what is tiktok error code 2433 and how to fix it

- axtly.com – what is the instagram map feature and how to enabl

- noepic.com – guide to adding locations to the instagram map way